Introduction of General Oil Expeller Presses

Generally used oil processing machinery have two types. One is hydraulic expeller press, the other one is screw expeller press. And pre-press adopts screw expeller press commonly.

|

|

|

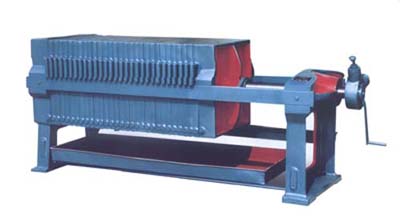

Hydraulic Expeller Press:

Transfer pressure to materials by oil, to make them expelled oil in static state. According to the power source of oil pump, there are two types, electric and manual. According to force ways for cake, the hydraulic oil p is vertical type and horizontal type. Vertical hydraulic expeller press have 1 oil tank fixed on base. A column shape of piston equipped in the oil tank. The top of piston joint with cake support plate into a whole. After pre-press, material is pressed into round cake with external cake rings. With 20 to 40 stacked cakes between cake support plate to top plate. There is thin underlay with holes between cakes for separation. The drive piston go up and create pressure to squeezing oil out from cakes. After extraciton finished, the oil pump stop pressing and the piston fall back. The residue cakes are discharged out. New material feed in. Like this, hydraulic expeller press can realize repeated intermittent oil pressing for 2 to 5 hours per time.

In the use of electric pumps, circulation oil system can be composed and operate several hydraulic expeller presses at one time. Horizontal hydraulic expeller press has the similiar structure and working principles with vertical type. It facilitate installation and oil flow smoothly without oil residue on cake rings. But the horizontal expeller presses need more area and auxiliary equipments such as heavy hammer, pulley and screw shaft etc. The pressure from hydraulic expeller press is very big with high extraction rate per time. The working parts is less, easy to maintenance. But the labor intensity cost high in cake feeding and discharging.

Screw Expeller Press:

Screw oil press is an equipment for extraction of food oils in dynamic pressing function, which make materials push forward continuously in press chamber. Except feeding hopper, press chamber is main working part, composed by a worm shaft and round cylinder press cages. There is two types of screw expller presses, single-stage and dual-stage. Single-stage press have only one horizontal press chamber. Dual-stage have a vertical press chamber for first press except horizontal. Worm shaft is composed by several screws and distance rings. Every screw have stated screw distance and screw depth. For a whole worm shaft, screw distance of screws is shortening from feeder to discharger and screw depth is shoaling gradually. So the volume of press chamber is smaller and smaller from input to output. When material come into press chamber, it is pushed to output along stages of worm shaft. The pressure gradually become larger till the oil is squeezed out in succession. Cylindrical press cage have trays between press bars, which form gaps for extraction of food oils. The squeezed oil flow out from the gaps.

Large screw expeller press also equip with scraper in press cage. The blade of scraper embed in press chamber, aim at every distance rings to avoid skid and return of material running in chamber. The scraper can also adjust the thickness of cake, thereby the chamber pressure can be controlled correspondingly to redcue oil residuce rate. In addition, large screw expeller press have the cake folder for bright surface of residcue cake. It is often accompanied by steam cooker to carry out cooking and pressing continuously.

The screw expeller press for pre-press is to use bigger pressure to press the oil material at rough. The prepressed cake feed into expeller press for continuous pressing or for solvent extraction of food oils. So the input and output of press chamber have bigger change. The production capacity of prepress is bigger, too.

Screw expeller press can work continuously with small labor intensity. The residue cake after extraction of food oils is thin and small, easy for use. But the wear and tear of main parts in press chamber need to change reguarly, which increased working cost.

Oil Press

- YZS Series Oil Expeller

- ZX Series Oil Expeller

- Large Scale Oil Mill Machinery

- YLX65 Filter Press

Pellet Mill

Pellet Stove

Biomass Briquette Plant

Roll Forming Machine

Flour Mill

Food Processing