Oil Extraction Machine With Large Yield

Comparing with mini oil mill, large scale oil extraction machine is a kind of oil mill machinery with larger volume and higher output. Stand-alone capacity of oil extraction machine ranges from 10-200 T/D. Compared with the mini oil mill used for household and small oil production line, oil extraction machine always used for oil pressing line in large edible oil refinery plant. Oil extraction machine usually use double-helix structure, compared to single-spiral structure has strong pressing capacity, and the oil rate is higher. Suitable for processing of oil in addition to the ordinary oil seeds and nuts, corn germ, sunflower, soybean seed, cottonseed, sesame seeds, coconut etc, can also deal with many special oilseed, such as hemp seed, perilla seed, amaranth seed, rubber seed, almond and prickly ash seed, etc. Oil extraction machine is suitable for both hot pressing and cold pressing . The edible oil quality is more pure and the color is lighter.

Cold Press Oil Extraction Machine

Cold press oil extraction machine is a kind of oil mill machinery which makes use of the clod pressing technology to press the oilseed without flaking and cooking at room temperature less than 65℃. The use of cold press oil extraction machine can well retain the nutritional ingredients in the edible oil, without the need of edible oil refining. Therefore, the edible oil pressed by the cold press oil extraction machine, and only the filtering treatment is required to obtain the cold pressed finished edible oil.

| Model | Capacity(T/D) | Power(KW) | Net Weight(KG) | Dimmension(MM) |

|---|---|---|---|---|

| LYZX12 | 5-6 | 22+0.75+1.1 | 4000(4300) | 3300(3580)×1000×2380 |

| LYZX18 | 6-12 | 37.7 | 3500 | 3176*1850*2600 |

| LYZX24 | 20-25 | 75+7.5 | 10500 | 4535×2560×3055 |

| LYZX28 | 40-60 | 45+11+1.5KW | 9600 | 3783×3038×3050 |

| LYZX32 | 60-80 | 90+75+1.5 | 12650 | 4832×2917×3236 |

Pre-press Oil Extraction Machine

Pre-press oil extraction machine is suitable for edible oil pre-pressing and twice pressing in the solvent extraction process.

- Model: YZY283

- Capacity: 140~160T/D

- Power: 50KW

- Weight: 9380kg

- Dimension: 3708×1920×3843mm

Send Enquiry Now!

| Model | Capacity(T/D) | Residual Oil Ratio | Power(KW) | Net Weight(KG) | Dimmension(MM) |

|---|---|---|---|---|---|

| YZY240 | 75-120 | 13-15% | 45 | 6800 | 4178*2870*3660 |

| YZY283 | 140-160 | 15-20% | 55 | 9380 | 3708*1920*3843 |

| YZY320 | 200-260 | 15-18% | 110 | 12650 | 4832*2917*3236 |

| YZY340 | 300 | 11-16% | 185 | 14980 | 4935*1523*2664 |

Large Scale Edible Oil Mill Plant

As an enterprise producing edible oil on a large scale, it is far from enough to satisfy diversified edible oil production with a single edible oil mill plant. AGICO Machinery provides you with complete edible oil production line equipment, from oil pretreatment, oil pressing section, solvent extraction process, edible oil refining process to edible oil filling, the oil mill machinery be used in each step of edible oil production machinery can be matched one-stop.

Edible Oil Pressing Process

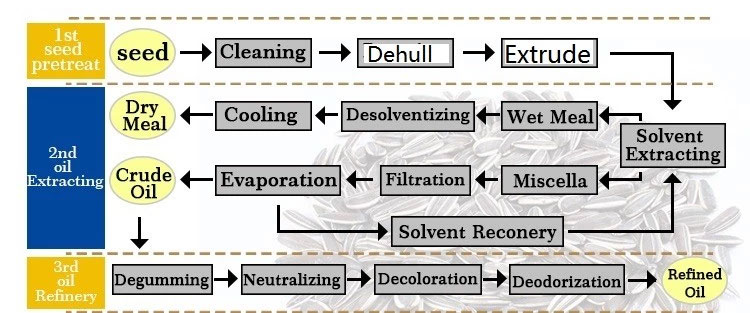

Unlike the physical pressing method, the extraction method of edible oil needs more precise steps to achieve higher oil yield.

Oilseed Pretreatment

In order to ensure the quality of edible oil, it is first necessary to clean the oilseed and remove impurities. If oilseed has a shell or peel, it needs the step of oilseed shelling and oilseed peeling. Oilseed cleaning tools used in oilseed pretreatment section mainly include vibrating sieve and gravity grading stoner.

Gravity grading stoner

Mainly responsible for removing stones and other impurities in the oilseeds.

Solvent Extraction Process

The solvent extraction process is to soak the treated oilseeds in the organic solvent which can dissolve the oil and leach the oil from the oilseeds by using the principle of chemical extraction. The main oil mill machinery used in the solvent extraction process includes oil seed extractor, solvent evaporator and desolventizer.

Oil seed extractor

Oil seed extractor is the equipment for chemical soaking of oilseed. After chemical extraction reaction, the miscella and wet meal were obtained.

Solvent evaporator

Solvent evaporator is used to evaporate the water and chemical solvent in the miscella to obtain crude edible oil.

Desolventizer

Desolventizer is a kind of oil mill machinery which removes residual solvents from wet meal by steam principle.

Edible Oil Refining Process

The crude edible oil treated by solvent extraction process still contains many solid impurities, which can not meet the edible standard of edible oil. Edible oil refining is the process of removing free fatty acids, phospholipids, colloids, waxes, pigments and odors from crude edible oil through a series of chemical and physical processes.

Oil degumming

Oil degumming is the process of removing colloidal impurities in crude edible oil by physical and chemical methods.

Oil neutralization

Neutralization process refers to the use of alkali neutralization method to remove free fatty acids in crude edible oil.

Oil bleaching

Oil bleaching generally uses a bleaching tower to remove pigments such as chlorophyll and carotenoids that affect the appearance of edible oil.

Oil winterization dewaxing and defat

Some edible oils also need to be winterized and dewaxed to remove some of the remaining solid fats and organic additives (binders and lubricants) from edible oils.

Oil deodorization

Oil deodorization is the process of removing some odorous substances derived from oil oxidation products in crude edible oil. The main equipment is deodorization tower.

Edible Oil Filling

The refined edible oil can be obtained by the oil refining process. These refined edible oil have met the edible requirements, can be filled and sealed. After completing the final packaging process, they will circulated into the market. The main oil mill machinery used in the edible oil filling process includes oil filling machine and linear sealing machine.

Oil filling machine

The oil filling machine is used to fill refined edible oil into barrels for sell to the market.

Linear sealing machine

The linear sealing machine is used to seal the oil drum after the filling process.

Successful Cases Of Oil Mill Machinery

Since establishment of AGICO Machinery more than 20 years, we provide customers with a variety of edible oil extraction machine for different materials, such as coconut oil extraction machine, palm oil extraction machine, soybean oil extraction machine, sunflower oil extraction machine, sesame oil extraction machine and other vegetable oil extraction machines.

In addition to the single oil extraction machine, our edible oil mill plant and edible oil refinery plant are also favored by customers all over the word. These edible oil production lines have been built and put into production in the local area, producing edible oil products for local customers, and at the same time bringing huge profits to the operators.

Part of Successful Edible Oil Mill Plant Cases

- 40t/d palm oil pressing plant and palm refinery plant project in Indonesia.

- Sunflower oil production line project successfully set in Uzbekistan. The sunflower oil production line includes two workshops, they are sunflower oil pressing workshop and sunflower solvent extraction workshop.

- Groundnut oil mill plant project in China. The customer purchased a total of 10 LYZX28 cold press oil extraction machines and YZY283 pre-press oil extraction machines.

- 80t/d fresh butter rendering equipment and 30t/d butter refinery plant project in Turkmenistan.

- 10t/d rapeseed oil refinery line project in Tibet.