H Type Chicken Cages

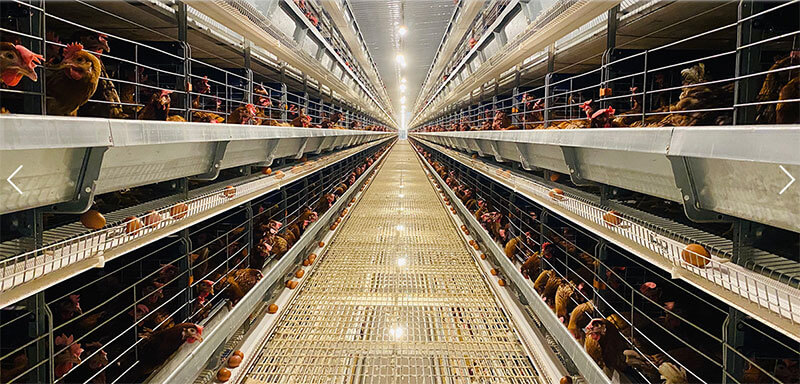

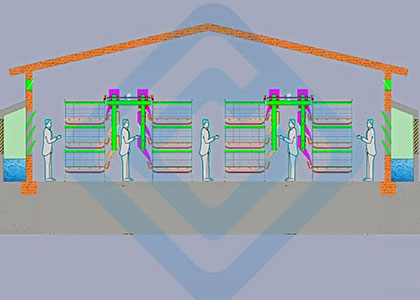

The design of the H type chicken cage is like a building. The cages layer by layer is stacked together to form a chicken cage system. H type chicken cages have gradually developed and become popular in recent years. Due to the increasing shortage of land resources, there is less and less land that can be used for laying hens. Therefore, more and more customers increase the density of laying hens, which greatly saves land. Compared with the A-type cage system, the H-type chicken cage system is more intensive. Generally, it can be stacked with 3-8 layers. Some chicken farms can even use as many as 8-10 layers of H-type chicken cages. H-type layer chicken cages are suitable for large-scale chicken farms with a higher degree of mechanization. The breeding capacity of a chicken house can easily reach 100,000.

AGICO focuses on the design and manufacture of automated chicken raising equipment. We have carefully developed the H-type layer chicken cage system, the H-type broiler cag system, and the H-type pullet cage system for our customers to meet the needs of various chicken breeding.

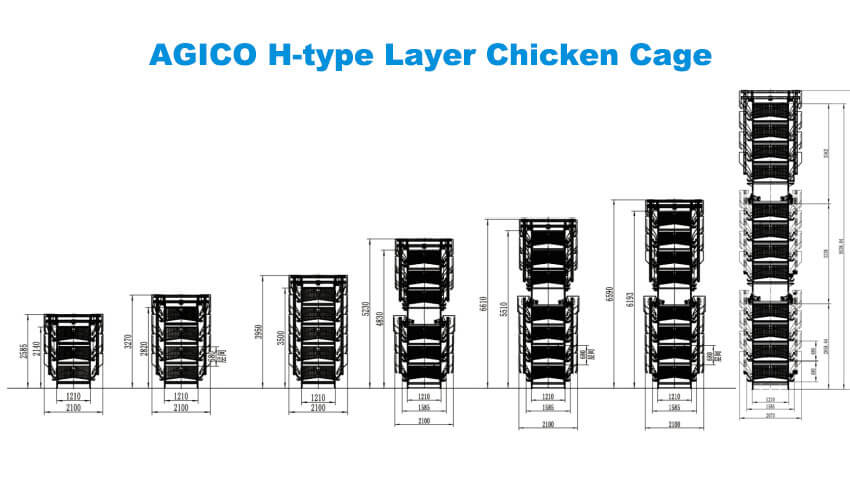

H Type Layer Chicken Cage System

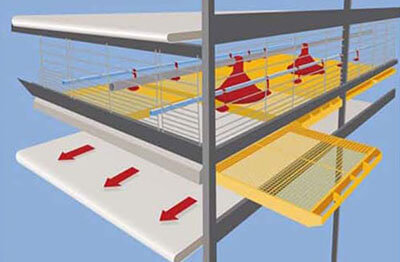

The H-type chicken cage system is composed of H-type chicken cages, automatic feeding system, automatic manure cleaning system, automatic drinking water system, automatic egg collection system, ventilation system, etc. H-type layer cages are usually 3-12 tiers, and a single cage can breed 8 laying hens. The specific parameters and structure are shown in the figure below.

| Tiers | Area/bird(cm²) | Birds/door | Dimension/door(mm) | Tier height(mm) |

|---|---|---|---|---|

| 3 | 450 | 8 | 600*600*480/390 | 680 |

| 4 | 450 | 8 | 600*600*480/390 | 680 |

| 5 | 450 | 8 | 600*600*480/390 | 680 |

| 6 | 450 | 8 | 600*600*480/390 | 680 |

| 7 | 450 | 8 | 600*600*480/390 | 680 |

| 8 | 450 | 8 | 600*600*480/390 | 680 |

| 12 | 450 | 8 | 600*600*480/390 | 680 |

Advantages of H-type layer chicken cage system

- The cage frame and cage accessories of the H-type layer chicken cage adopt the hot-dip galvanizing process, and the service life can reach 30 years;

- The feeding system adopts a patented homogenizer, which can maintain uniform feeding during use and prevent the feed from spilling;

- Combined with the actual situation, the manure cleaning system adds a secondary scraper design to make the manure removal effect more thorough;

- The drinking water system has added real-time monitoring equipment, which can realize automatic flushing and disinfection and water shortage alarm functions;

- The egg collection system adopts international advanced technology, and each layer of eggs adopts a staggered collection mechanism to avoid egg collision.

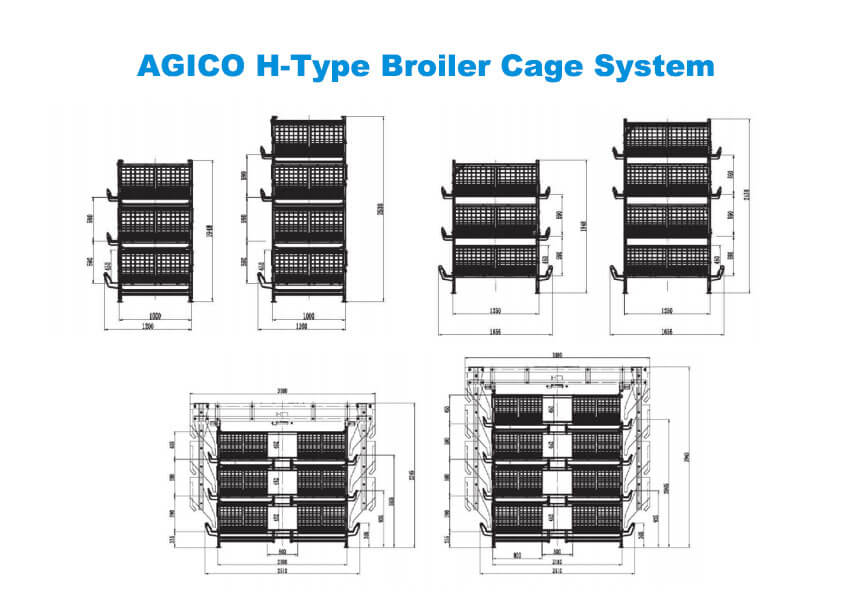

H Type Broiler Cage System

We designed H-type broiler cages for broiler breeding, making broiler breeding more factory-like, large-scale and automated. Our products are sold to many large-scale broiler farming companies and play a key role in successful farming. Our H-type broiler cages have better meat ratio and survival rate. In order to meet the needs of different customers, we have developed various types of H-type broiler cages.

| Tiers | Area/bird(cm²) | Birds/door | Dimension/door(mm) | Tier height(mm) |

|---|---|---|---|---|

| 3 | 500 | 20 | 1250*800*452 | 590 |

| 4 | 500 | 20 | 1250*800*452 | 590 |

| 3 | 543 | 23 | 1250*1000*450 | 590 |

| 4 | 543 | 23 | 1250*1000*450 | 590 |

| 3 | 546 | 32 | 1400*1250*450 | 590 |

| 4 | 546 | 32 | 1400*1250*450 | 590 |

Featured design

In order to facilitate the catching of chickens, the bottom grid of our H-type broiler cage adopts a pull-out design. The bottom net is pulled out, and the broilers in the cage can fall directly on the manure conveyor. The broilers can be transported outside the house by means of conveyor belts.

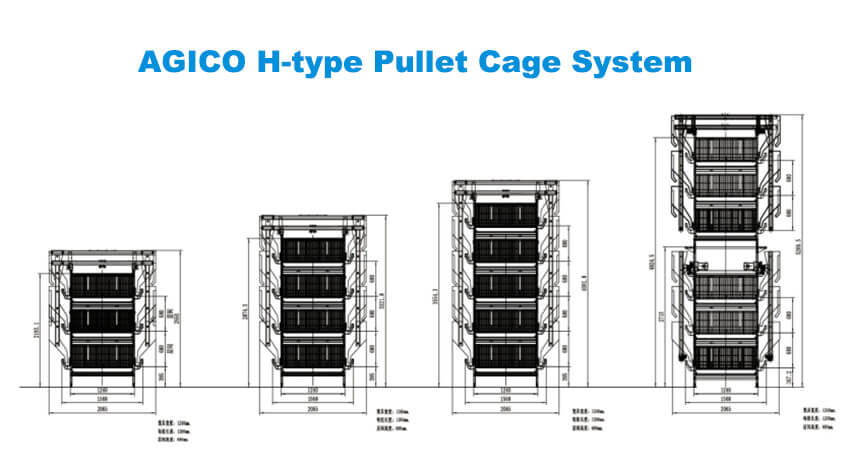

H-type Pullet Cage System

The H-type pullet cage system is specially designed for the rearing of pullets. The feeding mouth of the chicken cage adopts a beamless design so that the chicks can eat the feed more easily. The H-type pullet cage can create the best feeding environment for the chicks and lay a solid foundation for the growth of the chicks.

| Tiers | Area/bird(cm²) | Birds/door | Dimension/door(mm) | Tier height(mm) |

|---|---|---|---|---|

| 3 | 310 | 12 | 600*620*420 | 680 |

| 4 | 310 | 12 | 600*620*420 | 680 |

| 5 | 310 | 12 | 600*620*420 | 680 |

| 6 | 310 | 12 | 600*620*420 | 680 |

Related Products

AGICO's High-tech Chicken Cage Production Equipment

Digital bending machine

The galvanized wire can be bent quickly and precisely with a digital bending machine. The device has a robotic arm implanted with a digital microcomputer chip. Through the precision adjustment mode, the robot arm is controlled to operate and process the CNC integrated molding machine with high precision. This makes production more automated and faster.

Laser cutting machine and mesh welding machine

The laser cutting machine adopts the world's advanced laser cutting technology, which can accurately cut the material. The use of the automatic mesh welding machine makes the H-type chicken cage production line more automated.

Note: Min. Order: 500 bird

Commercial Poultry House

Commercial Poultry House Egg Tray Machine

Egg Tray Machine Quail Cage

Quail Cage