Building Automated Poultry Farm Transforming From Manual to Automated with Automation Equipment

In the dynamic landscape of poultry farming, a significant evolution has unfolded—a transition from manual to automated poultry farm systems, reshaping the industry's practices and efficiency. This transformation marks a pivotal shift towards precision and innovation within poultry farms.

The shift from labor-intensive manual methodologies to streamlined auto poultry farms has revolutionized the way poultry farms operate. This transformation entails integrating cutting-edge technologies to optimize processes, enhance productivity, and ensure superior bird welfare.

Emphasizing the implementation of automation in modern poultry farms is crucial. The move towards automated poultry farms harnesses technology's power to elevate efficiency, minimize labor requirements, and significantly improve overall operations. Embracing automation in poultry farming is not merely an upgrade but a strategic decision that leads to enhanced productivity and sustainable practices.

Manual vs. Automated Systems in Poultry Farming

Traditional manual methods in poultry farming have long been prevalent but come with inherent limitations. Manual processes, including feeding, watering, and waste management, heavily rely on human labor, leading to inefficiencies and constraints in farm management.

The advent of automation in poultry farm has been revolutionary, reshaping farm operations and redefining efficiency standards. Automation introduces advanced technologies that revolutionize traditional practices and optimize poultry farming processes, marking a transformative shift towards streamlined and efficient operations.

About the feeding equipment

In traditional chicken farms

In traditional chicken farms, in the absence of automated equipment, workers usually feed feed manually. This process includes the following steps:

- Feed preparation: Workers first prepare the feed, usually in bags or containers placed in the storage area.

- Manual feed handling: Workers manually move feed from large bags or containers to feed troughs or chicken houses. This may involve using buckets, shovels or other containers to move the feed to a specific location so the chickens can easily access it.

- Manual feed distribution: Once the feed is placed in the feed troughs, workers will manually distribute the feed into each feed trough or feeder. This process requires workers to feed each chicken one by one along each row of chicken houses, ensuring that each chicken gets enough feed.

- Observe and adjust: Workers may need to observe how the birds are eating and adjust feed distribution as needed. This may require regular checks and adjustments to ensure each chicken is getting adequate feed.

This manual method has the disadvantages of high dependence on manpower, low efficiency and uneven feed distribution. At the same time, since the entire feed feeding process relies on manual operation, it may lead to waste and uneven distribution of feed, thus affecting the growth and health of the chickens.

In modern automated chicken farms

In modern automated chicken farms equipped with fully automated feeding systems, the automated feeding systems use advanced technology and devices to supply feed to chickens in a fully automated manner. Here is a detailed description of this process:

- Feed supply: Feed is usually stored in centralized storage systems or silos. These feed systems deliver feed into the feeding system via conveyor belts, pipes, or other conveying devices.

- Metering and Distribution: Automated feeding systems are equipped with metering and dispensing devices to automatically distribute feed into feed troughs or feeders based on preset feed volumes and schedules. These systems accurately measure and control the amount of feed dispensed, ensuring each chicken receives the right amount of feed.

- Time control: Automated systems are often equipped with time control functions that can automatically provide feed according to a preset schedule and feeding frequency. This ensures that the feed is supplied to the chickens at the right time, ensuring that the chickens take feed regularly and quantitatively.

- Monitoring and adjustment: Some advanced automated feeding systems are equipped with monitoring devices that can monitor chicken eating status and feed levels. Based on the monitoring data, the system can automatically adjust the amount and frequency of feed supply to ensure that the chickens receive sufficient feed while avoiding feed waste.

The automated feeding system improves the efficiency and accuracy of feed distribution through efficient automation technology and precise control. This system not only reduces the need for manual operations, but also improves the accuracy of feed distribution and the growth efficiency of the chickens.

About the watering equipment

In traditional chicken farms

In traditional chicken farms, workers often provide water to the chickens manually without the help of automated equipment. Here is a detailed description of this process:

- Water source preparation: Usually, the water source may come from a faucet or bucket. Workers need to have an adequate supply of water ready for feeding within the chicken farm.

- Manual watering: Workers will provide water to the chickens manually using buckets, hoses, or other containers. They will go into the coop and add water to each feeder or trough as needed. This may involve moving buckets or hoses to each watering point and filling each watering point one by one to ensure each chicken has access to water.

- Regular inspections: Workers may need to regularly check water levels in water feeders or troughs to ensure there is adequate water. They need to add water in a timely manner as needed to ensure that the chickens have sufficient drinking water at all times.

This manual method has the disadvantages of high dependence on manpower, low efficiency and uneven water distribution. Since the entire water feeding process relies on manual operation, it may lead to uneven drinking water, and some chickens may not get enough water, which affects the health and growth of the chickens. At the same time, this method also increases labor costs and work burden.

In modern automated chicken farms

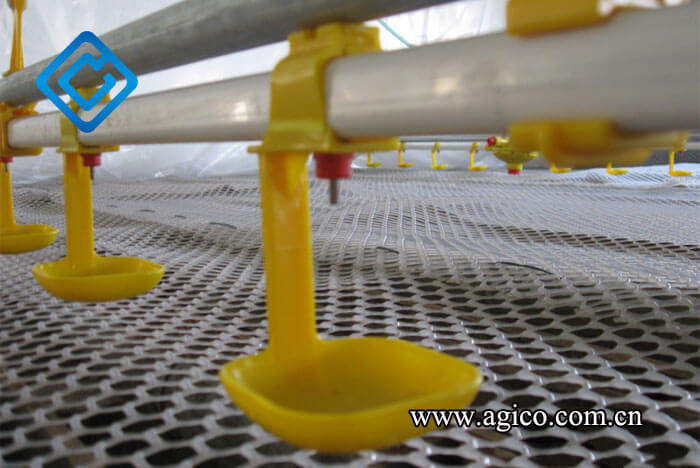

In modern automated chicken farms equipped with fully automated drinking water systems, the automated drinking water systems use advanced technology and equipment to provide water to each chicken cage in a fully automated manner. Here is a detailed description of this process:

- Water source preparation: The water source is usually centrally supplied, which can come from water pipes or water storage tanks. Water is delivered to the system's main water supply, such as a pipe, sink, or centralized drinking water installation.

- Water supply system design: The drinking water system is designed to ensure that each chicken coop is equipped with a water pipe or drinking fountain. These water pipes or drinkers are placed in every area of the chicken house to provide a source of water for each chicken.

- Automatic water supply: The system is set to automatically supply water to each drinking water point based on a preset schedule or sensor monitoring. Once the system detects a lack of water or insufficient drinking water at the drinking point, it will automatically start the water supply and send water to each drinking fountain or sink through pipes.

- Regulation and monitoring: Advanced automated drinking water systems are usually equipped with monitoring devices that can monitor water flow and water levels in real time. The system can adjust the water supply based on monitoring data to ensure that each chicken has sufficient water at all times.

- Regular maintenance: To ensure the normal operation of the system, the drinking water system requires regular maintenance and cleaning to ensure that the pipes are clear and the drinking fountains are clean and hygienic.

The automated drinking water system realizes fully automatic supply of water to chickens through efficient automation technology and precise control. This system improves the accuracy and efficiency of water supply, ensuring that each chicken can receive sufficient, clean drinking water, helping to improve the health and production efficiency of the chickens.

About Waste Management

In traditional chicken farms

In traditional chicken farms, handling waste such as chicken manure usually requires manual processing. Here is a detailed description of this process:

- Manual cleaning: Workers need to regularly enter the chicken coop or pen to perform cleaning work. They may use shovels, brooms, or other cleaning tools to clean waste from the coop by hand. This includes cleaning up feces, discarded feed, and other debris from the bottom of the coop.

- Waste Collection: Cleaned waste may be collected in centralized storage areas or bins. This waste may be temporarily stored in designated areas pending further processing or transportation.

- Waste Disposal: Waste disposal typically involves manual loading into a transport vehicle, such as a cart or tractor, and delivery to a suitable disposal site. Waste may be used as fertilizer or sent to landfill for disposal.

- Regular cleaning: Workers need to carry out cleaning and processing work regularly (usually daily or weekly) to ensure that the environment inside the chicken house is clean and hygienic.

This manual way of handling waste has shortcomings such as low efficiency, high labor intensity, and difficulty in ensuring environmental hygiene. At the same time, manual waste cleaning also increases the labor intensity and work burden of workers.

In modern automated chicken farms

Modern automated poultry farms are equipped with fully automated manure cleaning systems. These systems use advanced technology and devices to clean the manure in the chicken cages in a fully automatic manner. Here is a detailed description of this process:

- Conveyor system design: Automated manure cleaning systems include sophisticatedly designed conveyor systems, usually consisting of conveyor belts, pipes or other conveying devices. These devices are installed at the bottom of the chicken house and run throughout the chicken house.

- Manure collection: Manure from the chicken house is transported through these conveyor systems to a centralized storage area or waste treatment facility. The conveyor system automatically activates periodically or according to a preset schedule to collect waste from the chicken coop.

- Automated cleaning: A conveyor system automatically moves waste from the chicken house to a designated storage area or treatment facility. This process is fully automated and requires no human intervention.

- Waste Disposal: Collected waste may be used as fertilizer or sent to specific waste facilities for disposal. Some chicken farms may also be equipped with automated waste treatment systems to further process and utilize this waste.

- Monitoring and Maintenance: These automated systems are often equipped with monitoring devices to monitor the operation of the waste treatment system. Regular maintenance and cleaning ensure the normal operation of the system.

The automated manure cleaning system realizes fully automatic cleaning and processing of chicken house waste through efficient automation technology and precise control. This system improves cleaning efficiency, reduces manual labor, and ensures a clean and hygienic environment inside the chicken house.