Why do Chicken Cages Need Galvanized Coating?

The application of galvanizing technology in chicken raising equipment has a history of nearly 20 years. Galvanized chicken cages and various galvanized chicken raising equipment have been widely used in various chicken houses and farms.

If the chicken cage is made of iron wire alone, the iron wire mess is very easy to rust. Coupled with the stimulation of chicken manure and other substances, the iron wire is easily corroded. The rusted chicken cage will also damage the feet of the chickens, causing the chickens to become tired and sick. However, galvanized cage nets can effectively avoid these problems and effectively prolong the service life of chicken cages.

The application of galvanizing process on chicken cages is mainly divided into two types, cold galvanized chicken cages and hot-dip galvanized cages for chicken. Next, the chicken cage equipment for these two galvanizing processes will be detailed for you.

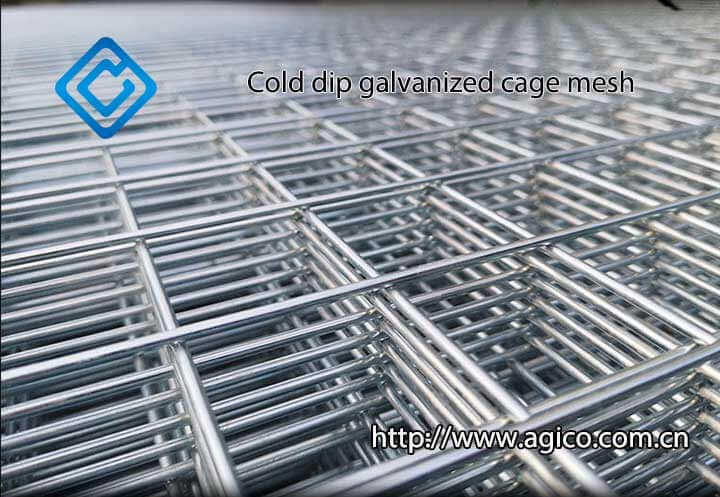

Cold Galvanized Chicken Cage

Electro galvanizing, also known as cold galvanizing, is a process for anti-corrosion treatment of workpiece surfaces through electrochemical principles. Electrolysis is used to attach a uniform, dense and well-bonded zinc layer to the surface of metal or other materials, and the amount of zinc on the surface is small, about 10-50g/m2. The cold galvanized coating can prevent corrosion, improve wear resistance, reflectivity, and enhance aesthetics.

| Tiers | Area/bird(cm²) | Birds/door | Dimension/door(mm) | Tier height(mm) |

|---|---|---|---|---|

| 3 | 500 | 20 | 1250*800*452 | 590 |

| 4 | 500 | 20 | 1250*800*452 | 590 |

| 3 | 543 | 23 | 1250*1000*450 | 590 |

| 4 | 543 | 23 | 1250*1000*450 | 590 |

| 3 | 546 | 32 | 1400*1250*450 | 590 |

| 4 | 546 | 32 | 1400*1250*450 | 590 |

At present, in large-scale breeding enterprises, 90% of them use various cold galvanized chicken cage products, and their smooth surface allows chicken manure to easily fall into the manure channel instead of staying on the mesh, causing damage to eggs and chickens. various types of pollution. Moreover, the smooth surface of the galvanized chicken layer cage can make the chickens stay on the wire mesh more comfortably without causing any damage to the feet of the chickens, which can effectively reduce the fatigue of chickens and can effectively avoid the feet of the chickens. damage and cause disease.

Hot-dip Galvanized Cages for Chicken

Hot-dip galvanizing is a method of immersing steel parts in molten zinc to obtain a metal coating. Usually, the thickness of the cold galvanized layer is 5~15um, while the thickness of the hot zinc layer is generally 35um, and the highest even reaches 200um. Hot-dip galvanizing has good coverage, dense coating, and no organic impurities. AGICO introduced advanced hot-dip galvanizing production technology from the United Kingdom, which ensures that the zinc layer is smoother and denser, and the production capacity of hot-dip galvanized chicken cages can reach 200 tons per day.

| Tiers | Area/bird(cm²) | Birds/door | Dimension/door(mm) | Tier height(mm) |

|---|---|---|---|---|

| 3 | 450 | 8 | 600*600*480/390 | 680 |

| 4 | 450 | 8 | 600*600*480/390 | 680 |

| 5 | 450 | 8 | 600*600*480/390 | 680 |

| 6 | 450 | 8 | 600*600*480/390 | 680 |

| 7 | 450 | 8 | 600*600*480/390 | 680 |

| 8 | 450 | 8 | 600*600*480/390 | 680 |

| 12 | 450 | 8 | 600*600*480/390 | 680 |

AGICO uses advanced hot-dip galvanized cage mesh, and uses high-precision CNC machine tools for positioning and cutting. The production line is equipped with fully automatic robot welding equipment to keep the welding depth of each solder joint consistent, thus effectively ensuring the quality of each piece of cage net product.

The company has introduced a high-tech automatic galvanizing production line. The thickness of the galvanized layer of the new galvanizing process is 5 times that of the traditional galvanizing layer. Therefore, the rust-proof and corrosion-resistant performance of the galvanized chicken cage far exceeds that of similar products.

The life of galvanized chicken cages can be more than 5 times that of similar products, and the service life is greatly extended, saving a lot of costs for chicken enterprises.