Flour Milling Process

Grain contain a variety of dust mustard, organic and inorganic impurities. In order to ensure the quality of flour and food safety, the grain pretreatment process is very necessary before flour milling.

According to the different crops, there are some differences in the grain pretreatment process. The following is the introduction of the wheat flour pretreatment process and the corn flour pretreatment process.

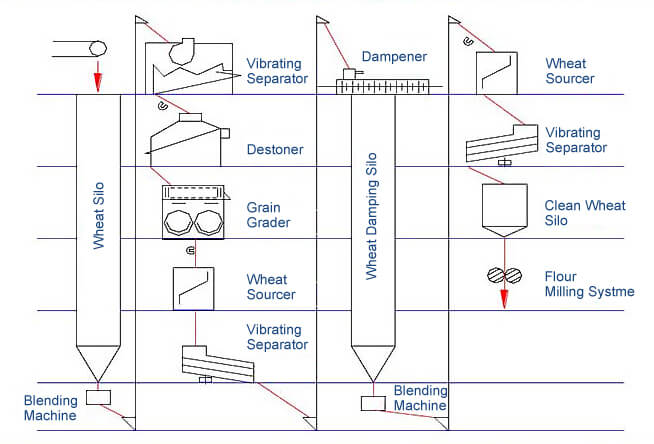

Wheat Flour Cleaning Process

Wheat Cleaning Process (early screening, demagnetization, debris and clean) ----- Gravity Grading Stoner ----- Sheller ----- Conditioning -----Wheat Flour Milling

Wheat Cleaning Process:

This process is mainly for the removal of impurities in wheat. The screening for primary screening, and the wheat clean, remove the sediment in wheat and magnetic impurities. This process requires grain cleaning equipments of rotary sieve and magnetic separator.

Gravity Grading Stoner:

Use gravity grading stoner to remove similar size stones in wheat and other high density and low density impurities.

Sheller:

Use the sheller for hulled wheat.

Conditioning:

Soften the wheat grain with water to make the next wheat flour milling process easier.

Wheat Flour Milling:

Through the above steps of wheat pretreatment, you can put the processed wheat into the flour mill for grinding.

Corn Cleaning Process Before Corn Flour Milling

Corn Cleaning Process (corn cleaning and screening)---- Sheller---Corn Germ Separation---Corn Flour Milling

Corn Clean:

The impurities present in the corn must be cleaned. Clean ways include use of corn screening, wind election and so on. Grain cleaning machine with rotary sieve, gravity grading stoner, magnetic separator and scourer.

Sheller:

Use the sheller for hulled corn.

Germ separation:

The use of advanced separation technology, guarantee the most pure protein.

Corn Flour Milling:

Through the above steps of corn pretreatment, you can put the processed corn into the flour mill for grinding.

Flour Milling Process

After wheat washing and wheat conditioning, the grinding steps of separating bran, endosperm and malt can be carried out. The whole flour milling process is divided into rough grinding, purification and fine grinding.

- Rough grinding is to slightly split the skin of wheat grains and take out of the coarse grains and flaky bran by the use of flour mill machine.

- In the purification step you need to use the purifier. According to the principle of specific gravity, the bran with lighter specific gravity will float up with the injected wind, so that the endosperm with heavier specific gravity can be screened out.

- Entering the fine grinding stage, the endosperm is flattened in the flour mill machine and then grinded while the malt is separated from the power by a separator. The obtained wheat flour was screened by a multi-layer rotary screen, and different grades of wheat flour were separated. The coarse fragments need to be reprocessed to remove the malt and reground to obtain fine flour fragments. And then fine flour fragments are grinded to produce superior flour.

Flour Compounded

Flour made from wheat with different hardness generally has different edible properties. Flour mill plant will mix the two wheat flour according to different proportions based on the needs of customers. Whole wheat flour as we know it is made from a combination of the endosperm and the bran powder. The flour mill plant also compounded special flour for different purposes, such as cake flour, noodle flour and bread flour, according to different requirements for food production. In addition, vitamins and minerals can be added to various flours according to demand to increase nutritional value and meet market demand.

Flour Packaging

The final step before the flour leaves the flour mill plant to the market is to separate into bags and seal the bags. According to the different sales demand, the finished flour packaged in different weights can enter the market for sale.