Oilseed Pretreatment Process

The oilseed pretreatment is a series of treatments such as cleaning, shelling, peeling, crushing, conditioning, and flaking before the oil prcessing. The purpose of the utility model is to remove impurities and make them into materials with certain structural properties, so as to meet the requirements of different oil extraction processes. According to the different varieties of oil materials and oil production process, the selected pre-treatment process and pretreatment oil mill machinery are also different.

In oil production process, oil pretreatment has an important impact on the oil production effect, not only because of the improvement of the structural properties of the oil to improve the speed and depth of the oil, but also on the various components of the oil effect product and by-product quality.

Oil Seed Cleaning

The oilseed in the harvest, in the process of transportation and storage will be mixed with some impurities, so the oilseed import production workshop after the need for further clean-up, the impurity content dropped to within the scope of technical requirements, to ensure that the process effect of oil production and product quality.

The impurities contained in oil can be divided into three types: organic impurities, inorganic impurities and oil impurities. Inorganic impurities are mainly dust, sediment, stones, metal, etc .; organic impurities are stems and leaves, hull, humilis, hemp, grain and so on; oil impurities are mainly pests and diseases, imperfect granules, heterogeneous oilseeds and so on.

Impurity removal method

1. Screening

Screening is the use of oil and impurities in the particle size of the difference, with the relative movement of impurities and sieve surface, through the sieve will be greater or less than the impurities in the oil removed. Common seed cleaning equipment includes vibrating screen, flat rotary sieve and so on.

2. Winnowing

According to the difference of oilseeds and impurities in the dynamic properties and the proportion of gas, the impurities in oil separation of wind. Winnowing can be used to remove the impurity and dust cleaning in oil, can also be used to remove the metal, stones and other heavy impurities, can also be used for oilseed hulling after separation of seed kernel and shell. The main equipment has a wind separator.

3. Gravity grading

The gravimetric method is based on the proportion of oilseed and gravel and the rate of suspension, and the purpose of grading with the combination of a certain movement characteristic and the inclined sieve surface and the air flow through the sieve surface. Major equipment is gravity grading stoner.

4. Magnetic separation

Magnetic separation is a method of removing metal impurities from oil by means of magnet. Although the content of metal impurities in the oil is not high, but they are very harmful, likely to cause damage to some equipment, especially the high-speed operation of the equipment, may even lead to serious safety accidents and equipment accidents. The main equipment has a permanent magnetic drum magnetic separator.

5. Mud and dust removal

Shape, size and oil seed similar or equal, and the proportion of the mud is also about to clean up. Rapeseed, soybean, sesame oil content more. The main equipment used is grinding machine, vertical round sieve and so on.

Oil Shelling And Peeling

Oil shelling

The purpose of the shelling is to improve the oil rate, improve the quality of crude oil and oil cake, reduce the wear and tear on the equipment, increase the effective production of equipment, facilitate the follow-up of the process and the comprehensive utilization of leather shell.

The main equipment: hammer shelling machine (peanut peel), roll-type shelling machine (castor bean peeling), disk shelling machine (cottonseed), knife board shelling machine (cottonseed shelling) (Cottonseed and soybean, peanut broken), centrifugal shelling machine (sunflower seeds, tung oil seed, camellia seed, walnut and other shelling).

Oil peeling

The purpose of oil peeling is to improve the protein content of the oil cake and reduce the cellulose content, improve the use of oil cake value. At the same time, it can also improve the quality of the extracted crude oil. The current need to peeling oil seed mainly soybeans, peanuts, rapeseed, sesame seeds and so on.

Send Enquiry Now!

Oil Seed Crushing

The oil must be crush by the large particles before the oil flaking. The purpose is to make the oil seed has a certain particle size to meet the conditions of the flaking. After oil seed crushing, the surface area of the oilseed is increased, which is beneficial to the transfer of temperature and moisture, and the softening effect is improved. For larger crushed oil cake, it must also be broken into smaller pieces of oil cake in order to be more conducive to leaching oil. Soybean generally crushing the particle size of 4-6, peanut broken particle size of 6-8 flap. Crushing equipment generally has a roller crusher.

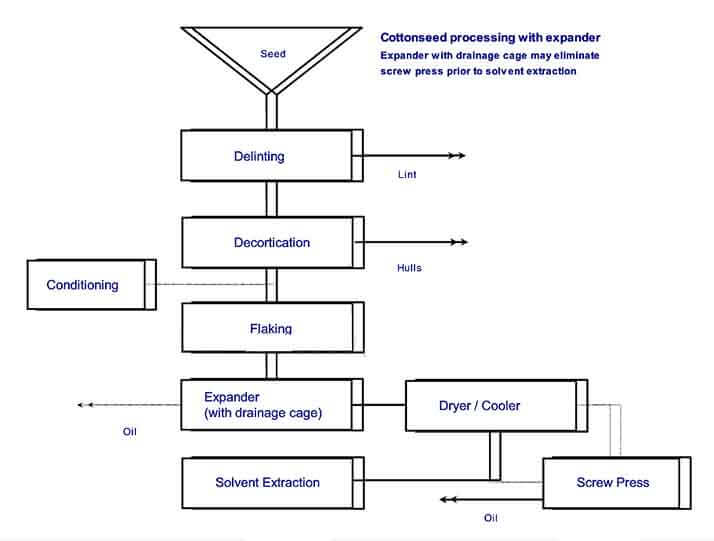

Oil Seed Conditioning

The purpose of conditioning is to adjust the oil temperature and moisture, so as to make the oilseed has a suitable elastic and plastic, reduce the degree of powder and sticky roller phenomenon, ensure quality. The soybean oil content is low, the plasticity is bad, generally must condition before the flaking. Cottonseed kernel contains the husk particle hard is not the same, also need to go through the conditioning. conditioning equipment generally has conditioning pot and drum conditioning pot.

Oil Seed Flaking

The purpose of the flaking is to destroy the cell structure of oilseed, increase the surface area of oilseed, shorten the distance of oil outflow, is conducive to the extraction of oil, but also help to improve the effect of steaming. The main equipment is the flaking rolling machine.

Gravity Grading Stoner Gravity grading stoner is widely used in oilseed processing and flour mill raw material processing, and also a kind of effective raw material cleaning equipment. When gravity grading stoner working, the oil seed from...

Vibrating Sieve Vibrating screen is a screening device for the reciprocating motion of the screen surface. The vibrating sieve has high cleaning efficiency, reliable work, so it is a kind of oil cleaning equipment which most widely used in...