How to Effectively Deal with Power Outages in Industrial Chicken Incubators?

How to Effectively Deal with Power Outages in Industrial Chicken Incubators?

The normal operation of industrial chicken incubators depends on a stable power supply system, and power outages can seriously threaten incubating embryos. The temperature and humidity fluctuations caused by power outages can stop the embryos from developing and lead to high mortality. In addition, power outages may also affect the automatic egg turning function, causing embryos to stick together or other problems due to long-term static conditions. Power outages are undoubtedly a thorny challenge for modern incubation equipment that relies on electricity.

Compared with the series of problems caused by power outages, we can take precautions in advance. Through reasonable solutions, we can effectively prevent or even avoid the impact of power outages and ensure the stability of industrial chicken egg incubator operations. We will introduce you to several effective solutions to prevent power outages from affecting hatching, including intelligent lightning protection systems for incubators, coal-fired power dual-purpose incubators, solar hatchery machines, etc. We will help users find a coping strategy that suits them and ensure the success rate of hatching.

The Impact of Power Outages on Incubation in Industrial Chicken Incubators

Power outages have many impacts on incubators, especially on incubation temperature, humidity, and automatic egg turning functions, which may pose a serious threat to embryo development.

1. The impact of a temperature drop on embryo development

The temperature in the industrial chicken egg incubator directly determines the normal development of the embryo. During the incubation process, constant temperature is the key to ensuring the continuous development of the embryo, and power outages will cause the temperature in the incubator to drop rapidly. If the temperature is lower than the normal range for a long time (usually around 37.5°C), the development of the embryo will slow down or even stop. In severe cases, the embryo will die. Especially in winter or cold areas, the temperature will drop faster and the harm caused by power outages will be more significant.

2. Humidity fluctuations may cause embryo dehydration or infection

Humidity is another important factor in the incubation process. When there is a power outage, the humidification function of the incubator is interrupted, causing the humidity in the industrial chicken egg incubator to drop rapidly. Low humidity can cause water loss in the eggs, dehydrating the embryo and affecting normal development. High humidity can cause bacteria to grow, increasing the risk of infection in the embryo. Humidity fluctuations are particularly dangerous for embryos in the late stages of incubation, as the eggshell is weak and more sensitive to environmental changes.

3. Power outage caused interruption of automatic egg turning function

The automatic egg turning function is set to prevent the embryo from sticking to the eggshell and is an important mechanism for promoting uniform heating. When the power goes out, the automatic egg turning system stops working, and the embryos may develop abnormally due to being in a static state for a long time, especially in the middle of incubation. If the egg turning function is interrupted for a long time, the hatching success rate may drop significantly, directly affecting the breeding benefits.

Solution 1: Intelligent Lightning Protection System

The intelligent lightning protection system is a power supply protection mechanism designed specifically for thunderstorms, which can effectively prevent damage to the incubator circuit caused by lightning strikes. Lightning weather may cause voltage mutation or power outage. The intelligent lightning protection system can quickly cut off abnormal currents through the built-in surge protection device to prevent the circuit from being burned. At the same time, this system can also quickly restore the power supply after a thunderstorm to ensure the continuity of incubator operation.

AGICO intelligent lightning protection system incubator

The industrial chicken incubator products launched by our company are all equipped with advanced intelligent lightning protection systems, which are particularly suitable for users in areas prone to lightning. These incubators not only have strong lightning protection capabilities but also have core functions such as automatic egg turning and precise temperature control, which can provide users with all-round incubation support. If you are worried about lightning problems, you might as well choose the incubator equipped with an intelligent lightning protection system that we recommend to you.

| Chicken egg | Duck egg | Goose egg | Pigeon egg | Quail egg | Power |

|---|---|---|---|---|---|

| 88 | 63 | 32 | 112 | 221 | 700 |

| 176 | 128 | 64 | 224 | 442 | 700 |

| 1056 | 756 | 384 | 1344 | 2652 | 1000 |

| 1232 | 882 | 448 | 1568 | 3094 | 1000 |

| 2640 | 1890 | 960 | 3360 | 6630 | 1600 |

| 6336 | 4536 | 2304 | 8064 | 15912 | 2000 |

| 16896 | 12095 | 6144 | 21504 | 42432 | 6400 |

Solution 2: Coal-electricity dual-purpose Incubator

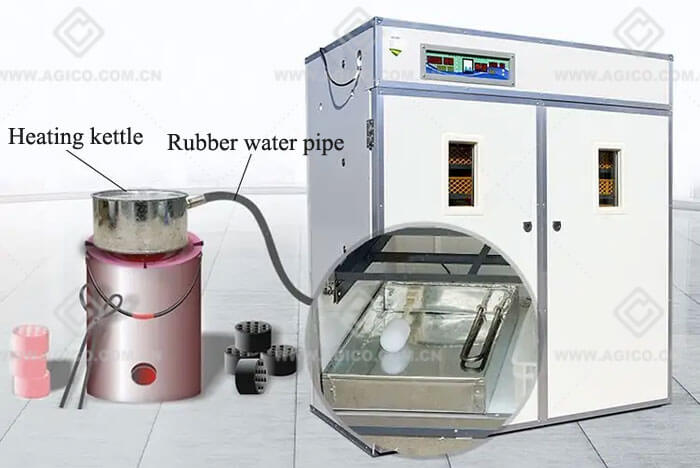

The coal-electricity dual-purpose incubator is an innovative device that combines modern power technology and traditional heating methods. It provides stable heat through built-in electric heating elements when power is normally supplied, and can switch to artificial heat sources such as coal for heating when power is off. This flexible heating mode allows the incubator to cope with a variety of power conditions, especially in areas with unstable power or in remote areas. The coal-electricity dual-use system becomes an effective solution to ensure the continuity of incubation.

| Chicken egg | Duck egg | Goose egg | Pigeon egg | Quail egg | Power |

|---|---|---|---|---|---|

| 176 | 128 | 64 | 224 | 442 | 700 |

| 352 | 252 | 128 | 448 | 884 | 700 |

| 1408 | 1008 | 512 | 1792 | 3536 | 1000 |

| 2816 | 2016 | 1024 | 3584 | 7072 | 1600 |

| 8448 | 6048 | 3072 | 10752 | 21216 | 3200 |

| 19712 | 14112 | 7186 | 25088 | 49504 | 6400 |

Operation steps during a power outage

- Prepare the heat source and kettle: When the power is off, fill the heating kettle with water and ensure that the kettle is well connected to the humidification water tray of the incubator. The two ends of the water pipe should be connected to the kettle spout and the humidification water tray inlet respectively to form a closed heating system.

- Heat the kettle: Place the kettle on a coal stove, gas stove, or other artificial heat source to heat it and ensure continuous heating.

Product recommendation: AGICO coal-electricity dual-purpose incubator

- Dual-mode heating: supports seamless switching between electricity and coal heating, and can operate stably regardless of normal power supply or power outage.

- Easy operation: during power outages, manual heating can be achieved with simple connection and heating operations, without complex adjustments.

- Wide range of applications: especially suitable for users with limited power conditions or in remote areas.

Solution 3: Solar Hatchery Machine

The solar hatchery machine is an innovative, environmentally friendly, and efficient device that converts solar energy into electrical energy through solar panels, providing a stable power supply for the incubator. Its unique feature is that it is equipped with an independent battery system that can store excess electricity during the day and provide continuous power support at night or during power outages.

| Chicken egg | Duck egg | Goose egg | Quail egg | Power | Size |

|---|---|---|---|---|---|

| 88 | 63 | 32 | 221 | 100W | 0.7×1.58×0.8m |

| 176 | 128 | 64 | 442 | 100W | 0.7×0.58×1.0m |

| 264 | 189 | 96 | 663 | 120W | 1.1×0.57×0.9m |

| 352 | 252 | 128 | 884 | 150W | 1.1×0.57×1.0m |

| 440 | 315 | 160 | 1105 | 200W | 1.1×0.57×1.1m |

| 528 | 378 | 192 | 1326 | 220W | 0.95×0.65×1.0m |

| 1056 | 756 | 384 | 2652 | 300W | 0.95×0.65×1.3m |

| 2112 | 1512 | 768 | 5304 | 350W | 1.37×0.8×1.5m |

| 5280 | 3780 | 1920 | 13260 | 500W | 1.75×1.05×0.8m |

AGICO solar hatchery machine recommendation

- High-efficiency solar energy conversion: equipped with high-quality solar panels and high-capacity battery systems, it can meet all-weather incubation needs.

- Intelligent control system: realizes fully automated operation, reduces manual intervention, and improves hatching efficiency.

- Rugged and durable design: adapts to various weather conditions and ensures long-term stable operation of the equipment.

Whether you are a beginner or a professional breeder, choosing the right incubator and backup plan is the key to ensuring successful hatching. By preparing in advance and responding appropriately, you can minimize the impact on the hatching process in emergencies such as power outages.